ATB Sludge treatment

In sludge treatment, the primary and/or excess sludge produced during wastewater treatment is thickened by removing water. This reduces the amount of sludge, whereas the dry substance content increases.

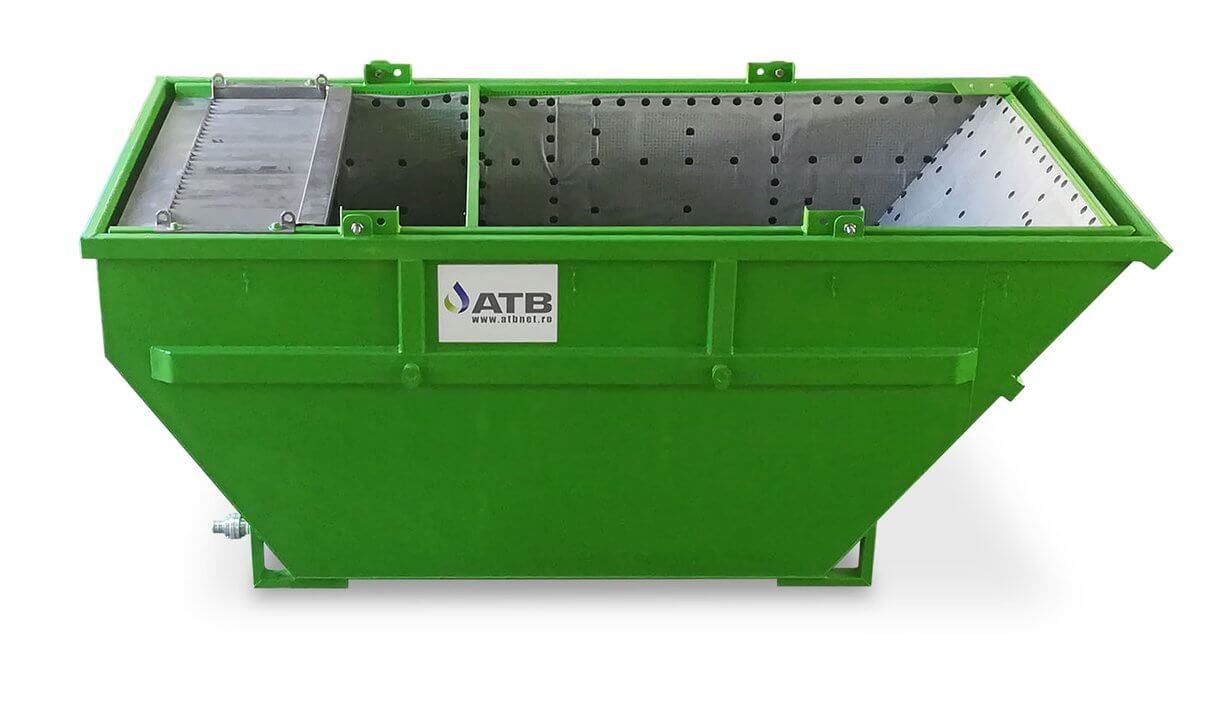

Static sludge dewatering container

- Mode of operation: Dewatering containers dewater all types of sludge effectively and economically. The inside of the containers is lined with a permeable double layer of acid and base resistant fabric. Collecting, storing, dewatering and transporting - all with one unit.

- Range: Available from 5 to 10 m3

- Material: Stainless steel V2A and V4A inner lining, filter cloth

- Applications: Sludge dewatering, general water-solid separation

- Your advantages:

✔ Inner lining made of stainless steel

✔ Suitable for waste truck transport according to DIN 30720

✔ Long service life

✔ Completely problem-free sludge drainage

✔ Stable sludge in a short time

✔ Low landfill costs

✔ Bottom, side walls and back wall works as filter surface

Sludge dewatering with filter bags

- Mode of operation: Primary or excess sludge from domestic and industrial wastewater treatment plants can be collected, dewatered and easily packaged using bagging equipment. Their basic component is the disposable textile bag. With the help of a metering pump, the sludge is treated with polymers and filled into bags for dewatering. Various optional functions allow a higher degree of process automation.

- Range: Wastewater treatment plants up to 2,000 p.e.

- Material: stainless steel tube frame, disposable textile bags

- Areas of application: Primary or excess sludge dewatering

- Your advantages:

✔ Simple installation and maintenance

✔ Easy retrofitting to existing wastewater treatment plants

✔ Easy disposal of the sludge – due to filling into bags

✔ Low investment and disposal costs

✔ Available with 2, 3, 6 or 12 bags